You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kalibrieren

- Thread starter Richtel

- Start date

Richtel

Well-known member

Richtel

Well-known member

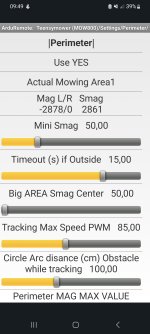

Same driving behavior as seen in the videos above. I also think that if you make an arc to find the wire again, this circle or radius is too small. It no longer reaches the wire, but is already at 360 degrees in front of it. The arc would have to be larger. but doesn't explain why he always wants to get away from the wire instead of following it....

It's not OK something is wrong.Hello,

Seems to work quite well but it only reads the left perimeter receiver!?

Try to set again YES and NO in the Read the 2 coil setting.

You need to see the 2 perimeter coil value.

I make a video.

Here the video.OK, I turned it back on after a few hours and now both work.

Great, now it’s time to continue testing. but great job so far!!!

First of all the motor setting need correct value according RPM vs PWM.

It's mean that PWM and RPM real time value need to be near the MAX one when mower run on flat ground

View attachment setting motor.mp4

In the video it's near RPM 30 and PWM 80 real time value for RPM 34 and PWM 97 max value

Tracking Video IN THE 2 COIL Version:

View attachment tacking1.mp4

View attachment tracking2.mp4

Mower roll CW (clockwise) when coil left is outside .

If mower reach perimeter with the right coil first and if left coil is inside at the end of the braking phase mower roll CCW (counter clock wise)

Here the console data:

In straight line MAG left coil is near -14000 and right one oscillate between 2000 and -2000 (IN/OUT transition)

View attachment tracking console.mp4

View attachment tacking1.mp4

View attachment tracking2.mp4

Mower roll CW (clockwise) when coil left is outside .

If mower reach perimeter with the right coil first and if left coil is inside at the end of the braking phase mower roll CCW (counter clock wise)

Here the console data:

In straight line MAG left coil is near -14000 and right one oscillate between 2000 and -2000 (IN/OUT transition)

View attachment tracking console.mp4

Last edited:

Start from station using button.

When button is pressed:

Mower send wifi data to sender to start (if no wifi ,sender start only when mower leave the station)

Wait 6 secondes (Optional door garage opening duration : need dev on the sender side code)

Reverse

Roll

TEST if the sender signal is OK

Start to mow or error if no signal

When button is pressed:

Mower send wifi data to sender to start (if no wifi ,sender start only when mower leave the station)

Wait 6 secondes (Optional door garage opening duration : need dev on the sender side code)

Reverse

Roll

TEST if the sender signal is OK

Start to mow or error if no signal

Attachments

Go to Dock.

One RFID tag is locate near station to reduce docking speed,You can see that at second nr 27

View attachment dock1.mp4

in the video

One RFID tag is locate near station to reduce docking speed,You can see that at second nr 27

View attachment dock1.mp4

in the video

In your video i can see that you have not a straight line before the docking station, so PID tune have trouble to have a perfect straight docking .Hello,

Seems to work quite well but it only reads the left perimeter receiver!?

Richtel

Well-known member

So actually the wire is right under the station, it sometimes makes little swings on the straight line.

Well, I still have problems with the wire in places.

I have the impression that he is now driving further out until he stops because of the wire.

I have now replaced the MPU. because he was swaying back and forth as he was driving out. that could be IMU.

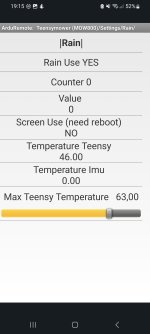

Since the last change, I no longer have a temperature display for the IMU. Is it wanted like that.

At first I blamed it on my supposedly defective MPU, but I don't have a temperature display on the new one either!?

Well, I still have problems with the wire in places.

I have the impression that he is now driving further out until he stops because of the wire.

I have now replaced the MPU. because he was swaying back and forth as he was driving out. that could be IMU.

Since the last change, I no longer have a temperature display for the IMU. Is it wanted like that.

At first I blamed it on my supposedly defective MPU, but I don't have a temperature display on the new one either!?

Attachments

So actually the wire is right under the station, it sometimes makes little swings on the straight line.

Well, I still have problems with the wire in places.

I have the impression that he is now driving further out until he stops because of the wire.

I have now replaced the MPU. because he was swaying back and forth as he was driving out. that could be IMU.

Since the last change, I no longer have a temperature display for the IMU. Is it wanted like that.

At first I blamed it on my supposedly defective MPU, but I don't have a temperature display on the new one either!?

It's normal I remove this on the last version ,because i am not sure that it not hang I2C line on random duration.I no longer have a temperature display for the IMU

Try to run slower on perimeter .

Richtel

Well-known member

I was just testing again with a new MPU but something doesn't seem right. It had already worked wonderfully, no question, we saw it on the video.

Now he's just talking nonsense again. I suspect that it could have something to do with the overload of the CPU, like in the console!?

The teensy runs at 600mhz and has a new MPU on it but something still seems to be bothering me.

Could it possibly be because the MPU is plugged in and perhaps it would be better to solder it, as Sefan once said!?

Now he's just talking nonsense again. I suspect that it could have something to do with the overload of the CPU, like in the console!?

The teensy runs at 600mhz and has a new MPU on it but something still seems to be bothering me.

Could it possibly be because the MPU is plugged in and perhaps it would be better to solder it, as Sefan once said!?

Attachments

No.I never solder MPU and it is not use while tracking.Could it possibly be because the MPU is plugged in

Check the IMU value when mower is working in bylane mode to see if it is ok .

Did the test IMU work ?

Issue is in the motor setting MaxPWM or maxRpm, mower rotate really too fast.

Can you share the console with the setting motor and mower running on flat grown like i did here:

Check again the test ODO to see if distance between wheel is OK (rotate 360) And reduce the speed max in pwm

Loop not OK is also normal in this case because lot of data are send to arduremote.

View attachment setting motor.mp4

Last edited: